Pallets are applicable in most industries for stacking, storing, and protecting goods. Technicians employ forklifts and jacks to handle the pallets safely. It is essential to employ pallets for goods stacking and safe transportation. Almost every consumer or industrial product has spent some time on a pallet.

Pallet manufacturing requires a range of materials. Wood is the most used material, accounting for 95 percent of global pallet consumption. The remaining 5% of the market employs plastic and metal pallets.

Understanding Wooden Pallets

Wood provides the robustness and affordable initial cost necessary to meet the majority of requirements. Wooden pallets are widely accessible, reasonably priced, and environmentally friendly.

From a pricing perspective, it seems logical that wooden pallets dominate the market. The desire to be competitive drives the decision to employ wooden pallets by many businesses.

Additionally, wood has certain extraordinary benefits for pallets. Manufacturers employ lumber wood to design and put together custom wooden pallets. Besides, you can use a variety of wood (softwood/hardwood) to manufacture pallets.

Wood benefits from versatility in terms of reaction time and inexpensive beginning costs for specialized designs.

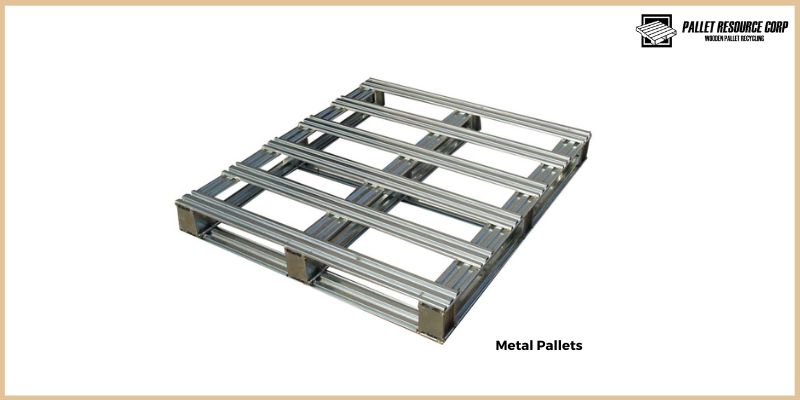

Understanding Metal Pallets

Although wood pallets have high strength and affordability, they have certain limitations. To overcome these limitations, there are metal pallets. You cannot use wood pallets for a load of more than 4,000 pounds. For such a purpose, you should employ metal pallets. Metal pallets are best for operations that need outside storage and transportation. Such pallets have to withstand harsh climatic conditions.

Metal functions well across the broadest temperature range when compared to wood and plastic. Metal pallets make sense in areas with a lot of combustible products. You cannot ignite metal at high temperatures. Additionally, metal performs best in freezing conditions. Wood pallets become fragile in harsh weather conditions.

Metal is easy to clean and difficult to contaminate.

Steel and aluminum are the two most prevalent metal pallet materials. Choosing between the two is determined by whether cost or weight is more crucial to your company. Aluminum pallets are more expensive.

Professionals recommend metal when a lightweight yet sturdy pallet is required for air freight transportation.

The cost of pallets has an influence on the final cost passed on to customers.

When expedited delivery necessitates air transport, the relative lightness of an aluminum pallet saves money.

Aluminum becomes a choice in situations with moisture since it does not corrode like steel pallets.

According to the experts, businesses can use aluminum and steel pallets in a closed loop to save time and money.

Metal pallets offer several benefits over their wooden counterparts, but they cannot replace wooden pallets in the coming ten to fifteen years.

Summary:

Are you in search of high-quality, durable pallets? For more information, call Pallet Resource Corporation of Blaine, Minnesota, at 763-792-2882.