With the use of pallets, you can improve business processes, functions, and the efficiency of the supply chain. Good pallets are helpful in improving both overall business revenue and customer satisfaction. The crucial thing to consider is the quality of wooden pallets. According to experts, you should opt for heat-treated and high-quality wooden pallets. Along with this, you will have the option to choose between softwood and hardwood for your pallets. How will you make an informed decision? What type of pallet is better for your business requirements?

What Do You Mean By Softwood And Hardwood Pallets?

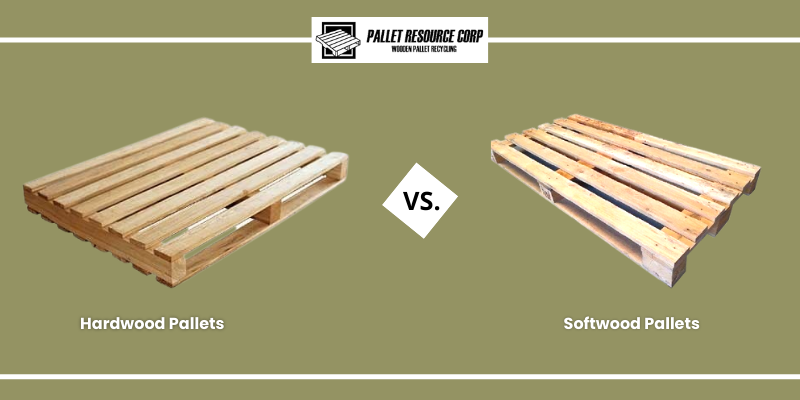

While manufacturing wooden pallets, technicians choose to use either softwood or hardwood. For more than a decade, businesses have found the application of hardwood pallets beneficial for their business. They offer high strength, reliability, and durability in the supply chain. But, in recent years, there has been an increasing demand for softwood pallets. This is probably due to affordable prices and easy availability.

Experts have been comparing the two wood types to know which one is better for a business. You have to consider certain factors to make the comparison, such as…

- Availability and Cost

- Weight Capacity

- Weight Of Pallet

- Service Lifespan And Repairability

Hardwood Or Softwood?

Hardwood is different from softwood in terms of density and strength. Softwood does not have high strength and density like hardwood. Moreover, hardwood has the potential to retain its size and shape under high temperatures and pressure. Softwood can easily break off with increasing pressure. Sometimes, softwood bends when the load or pressure increases. Besides, hardwood trees are more common than softwood trees. Some hardwood trees you can use for pallet manufacturing are maple, hickory, mahogany, walnut, teak, and oak.

Softwood is not low quality or weak. It has a resilience similar to hardwood. But the trees from which it is derived are softwood. The demand for softwood is high because of its ease of handling. Some tree species of softwood are pine, juniper, and redwood.

What Factors Can Influence The Choice Of Wood For Pallets?

#1 Availability Of Wood And Its Cost

The growth of hardwood is slower than softwood. Therefore, the availability of softwood is higher in the market right now. The trees grow faster and are easy to replenish.

Sometimes businesses are ready to pay a hefty price for harder-to-get hardwood because of its strength and high density.

#2 Weight Maintaining Capacity Of Wood

As the density of softwood is low, it has a lower capacity to manage weight. Hardwood can handle a heavier load since it has a higher weight capacity.

#3 The Weight Of The Pallet

The density of hardwood is higher. It makes hardwood pallets heavier than softwood pallets. The handling of hardwood pallets is heavier due to their weight. You can easily handle softwood as it is lighter. The heaviness of pallets can increase the fuel cost(s) of transportation.

#4 Service Life And Repairability Of The Pallets

Softwood has better repairability than hardwood. It is easy to cut, replace, bend and repair. This is what makes softwood more in demand than hardwood. But the hardwood pallets will have a longer service life; Hardwood is made from lumber and has the highest durability.

Summary:

Choosing between hardwood and softwood can be a difficult decision. In such situations, you should take recommendations from experts. If you want to get the best wood pallets for your business, consult Pallet Resource Corp. They are a leading supplier of the highest quality wood pallets. Pallet Resource Corp. of Blaine, Minnesota, offers wooden pallets, recycling services, and more; Please call 763-792-2882 for more information.